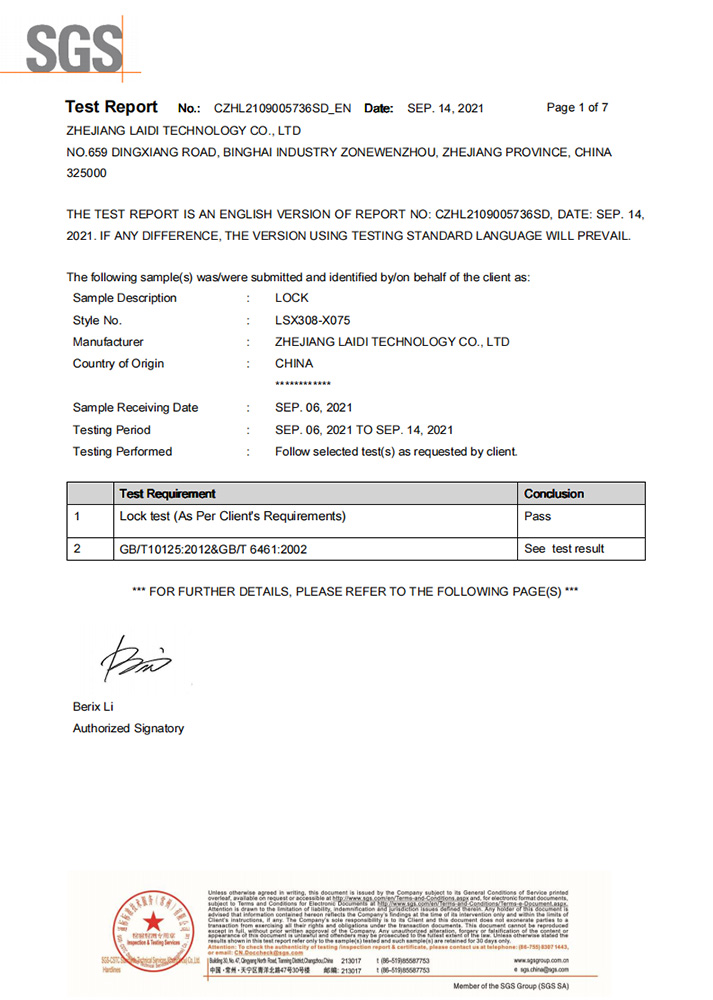

Zinc alloy material conforms to GB/T13818--2009 standard.

Aluminum alloy material conforms to GB/T1196-2008 standard.

Stainless steel conforms to GB/T1220 standard .

There are a total of 12 200-ton power die-casting machines, making the product denser and no sand inclusion on the surface.

There are a total of 10 large milling machines and 6 high-precision punches, ensuring minimal error.

We have a total of 20 semi-automatic tapping machines, which can simultaneously tap multiple products, with low cost and high efficiency, shortening the delivery cycle.

There are a total of 22 fast, slow and automatic polishing machines. The products are polished repeatedly manually to achieve a fine and smooth surface.

Multiple thickened plating or oxidation layers, with uniform color, no gaps, and no black spots.

There are 5 packaging lines in total, which are fast and low-cost.

The Quality Department has inspectors in die-casting, milling and cutting, drilling and polishing workshops to ensure that each product meets standards.

Strictly selection of high quality and famous brand environmental protection zinc alloy, aluminum alloy and stainless steel material.

In the finishing process, the size of product is checked and adjusted to meet the unified standard, in order to offer the basis to finished product assembly, inspection and instruction of installation

After electroplating is completed, it is necessary to compare with the original sample by color tester,to ensure that the color is within the tolerance range of color.

To test the resistance of the coating under acid and alkali condition,by 72 hours of neutral salt spray test.

Inspectors determine whether the product has sand inclusion, blistering and flaw to prevent defective products from flowing to the market.

whether the door handle can rebound by pressing down and releasing the handle.